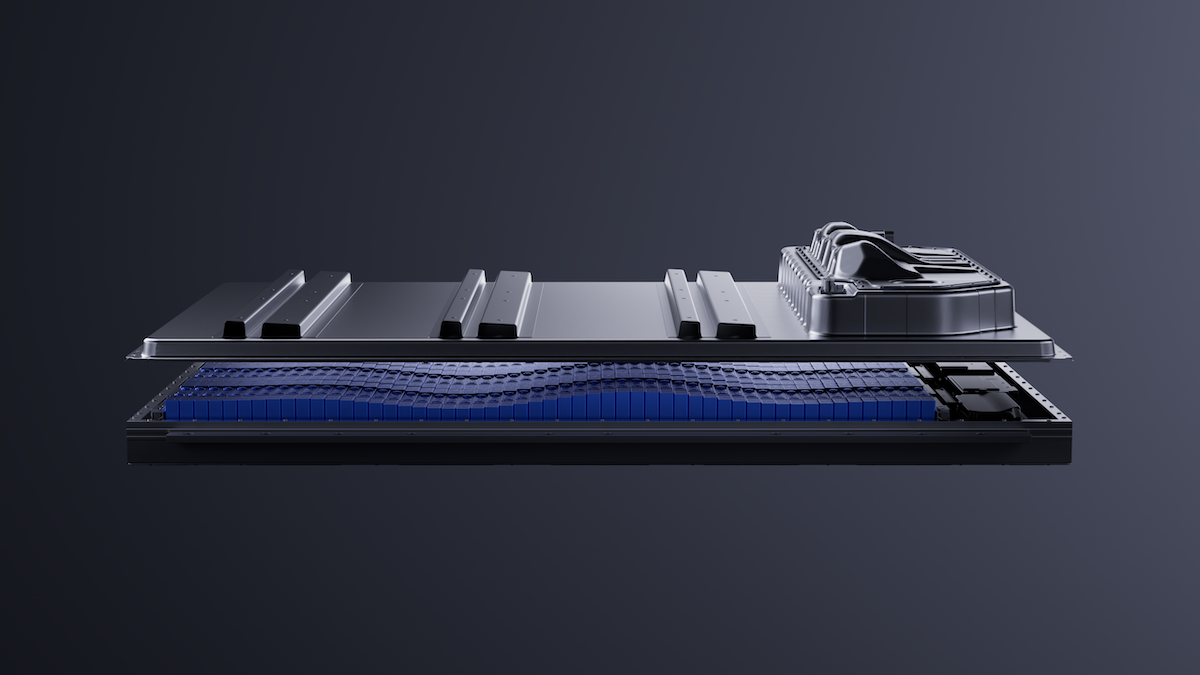

On the first day of the show, Rimac Technology announced that it had signed a memorandum of understanding with ProLogium and Mitsubishi Chemical Group to further develop ProLogium’s “superfluidized all-inorganic solid-state lithium ceramic battery.” The term “superfluidized” refers to a solid electrolyte that behaves at the electrode interface like a liquid, solving the long-standing problem of high resistance in solid-state batteries where ions require mechanical pressure to pass between the electrolyte and the electrode. The Next-Gen battery pack on display was a 100-kWh module using an NMC 90-5-5 chemistry paired with a 100% silicon anode, packaged in a soft-pouch cell-to-pack (CTP) format. Its performance figures demonstrated notable advantages, including output power of up to 850 kW, compared to 824 kW in the current Evo pack. Charging performance was significantly improved, with 10% to 80% charging achieved in just 6.5 minutes (at over 350 kW), compared to 16 minutes for the Evo. Equally impressive was its low-temperature performance, maintaining 95% of its capability even at -20°C, eliminating the need for a separate heating system, and allowing thermal management through a refrigerant loop connected to the vehicle’s air conditioning system. The overall weight is around 385 kilograms, about 85 kilograms lighter than the Evo, bringing corresponding improvements in power and energy density. Rimac aims to begin production in the fourth quarter of 2027, though given that the agreement is still at the memorandum stage, the timeline remains uncertain.

One of CATL’s highlights at the show was the “Shenxing Pro” battery, developed specifically for the European market with a focus on fleet and corporate vehicle applications. Its main selling points are durability and residual value retention, with a service life of up to 12 years or 1 million kilometers, and the ability to maintain 70% of its original capacity after 10,000 charge-discharge cycles. The pack is designed with 122 kWh of capacity using LFP chemistry, balancing cost and safety, and supports rapid charging from 10% to 80% in just 15 minutes. The system incorporates CATL’s latest NP 3.0 chemistry, interpreted as either “Next Phosphate” or “No Propagation.” The latter emphasizes that even in the event of thermal runaway, the battery is designed to prevent fire and smoke from spreading and can even continue delivering power long enough for the driver—or an autonomous system—to safely park the vehicle. These durability features help improve resale values and reduce total lifecycle costs, aligning particularly well with European corporate and fleet market demands for long-term stability.

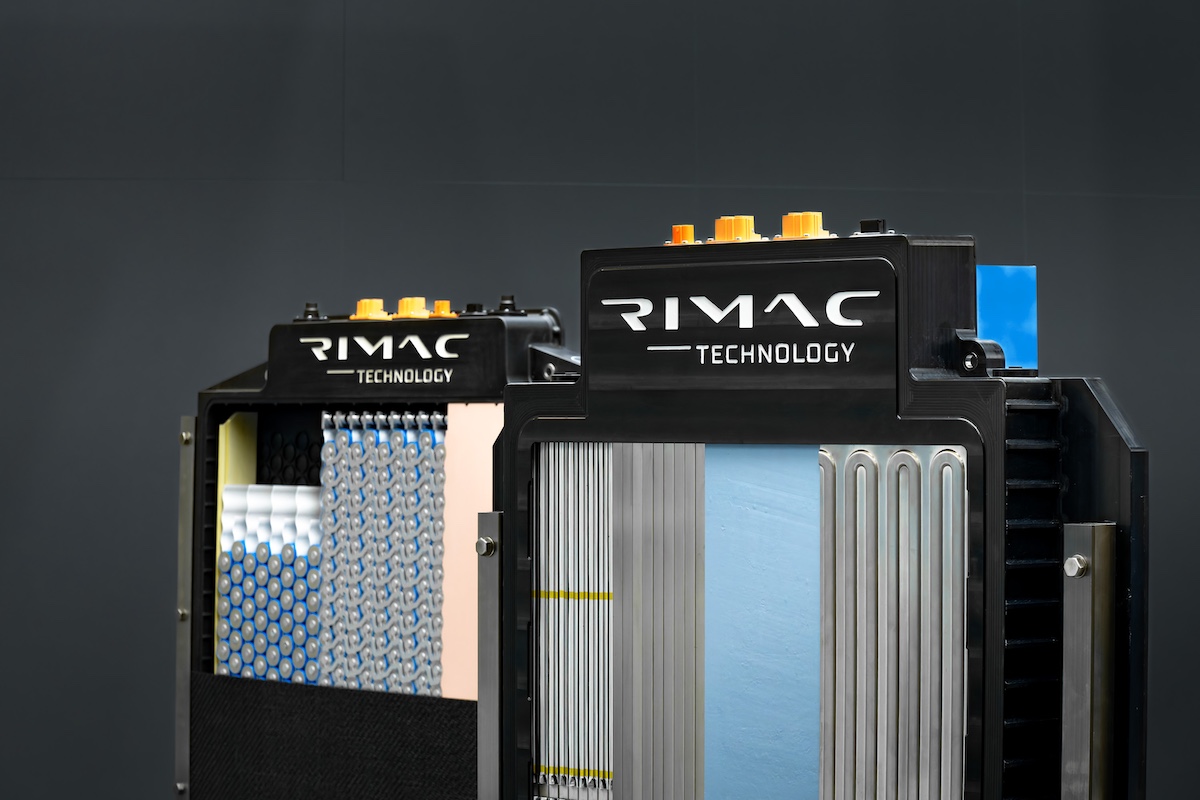

Another eye-catching innovation was CATL’s “Freevoy” dual-power concept battery. Unlike the mixed design previously pursued by Our Next Energy (ONE), CATL’s approach adopts a zoned architecture, placing LFP and NMC cells separately within a single pack. This opens multiple possibilities, such as enabling independent cooling systems and battery management systems for each zone, separating high- and low-voltage modules for improved safety and operational flexibility, and even isolating thermal runaway protection for each section to reduce overall risk. At the show, visitors could interactively “mix and match” different chemistry combinations, with charts illustrating the relative pros and cons of each. Although this concept remains far from commercial deployment, it offers the industry a thought-provoking direction—whether it is possible to balance range, safety, and cost without being locked into a single chemistry.

Overall, the new battery technologies on display at the IAA Munich Auto Show reveal several key trends. First, solid-state batteries are gradually moving into the technology validation stage. Rimac and ProLogium’s collaboration demonstrates breakthroughs in low-temperature performance and fast charging, which, while still years away from commercialization, are strengthening industry confidence. Second, durability is emerging as a critical factor in the European market. CATL’s Shenxing Pro addresses the needs of fleets and leasing sectors, signaling that beyond performance, the combination of long life and low lifecycle cost will become a differentiating advantage. Finally, exploration into multi-chemistry solutions, while still conceptual, suggests that battery design thinking is shifting toward modularity and hybridization, potentially enabling flexible adjustments tailored to different applications.

Taken together, whether it is solid-state, long-life LFP, or dual-chemistry concepts, all point to a common conclusion: batteries are no longer just energy storage devices—they have become the central technology that determines vehicle performance, safety, cost, and overall market positioning.