Neodymium magnets are known for their strong magnetic properties and heat resistance, and have long been widely used in high-performance motors, particularly as a critical material in the EV sector. However, to improve their heat resistance, traditional magnets must be supplemented with heavy rare earth elements such as terbium and dysprosium—materials heavily dependent on Chinese supply. As a result, global automakers face risks when access to rare earths is restricted. For example, Japan’s Suzuki Motor suspended production of its Swift compact car in May 2024 due to rare earth shortages.

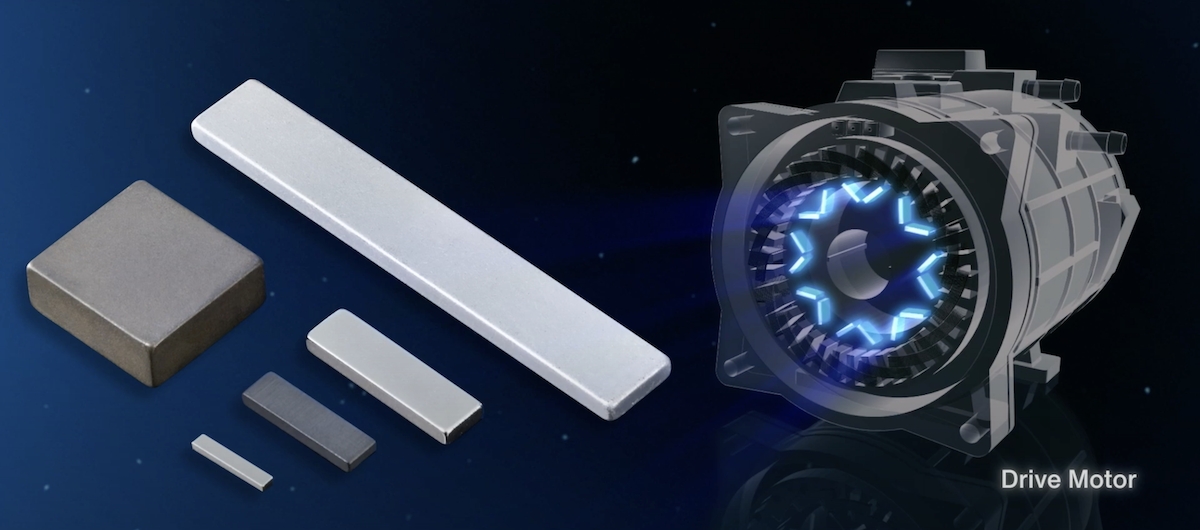

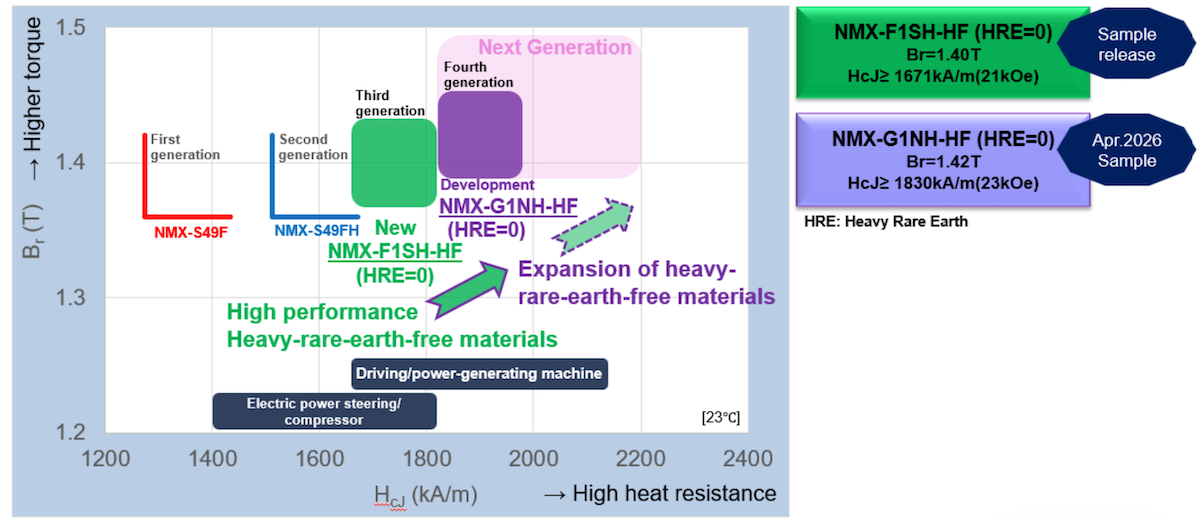

Proterial has now successfully developed two types of neodymium magnets that do not rely on heavy rare earth elements. The first type has already begun sample shipments from the company’s mass production facility, while the second version—featuring enhanced heat resistance—is scheduled for sample release in April 2026. According to the company, these new magnets can be seamlessly integrated into existing EV motor designs and can be mass-produced using mainstream manufacturing processes. With flexible shapes and cost competitiveness, they require little to no changes to current motor designs by EV manufacturers.

Although Proterial is not the first to enter the rare-earth-free magnet field—Daido Steel, for instance, has previously launched similar products—Daido’s solution requires modifications to motor geometry and cooling systems to accommodate differences in magnetic output. In contrast, Proterial’s new technology maintains high performance without altering the motor’s structure, demonstrating greater practicality and scalability.

From a supply chain management perspective, Proterial’s innovation not only helps reduce dependence on Chinese rare earth resources, but also has the potential to steer the EV industry toward a more sustainable and controllable direction. As the EV market continues its rapid expansion, key materials that support large-scale production and ensure supply stability will become increasingly important factors in how automakers choose their suppliers.

Although it may take some time before neodymium magnets are fully adopted in the market, this technological breakthrough has undoubtedly opened new possibilities for EV magnet materials and provided a significant boost to the resilience and autonomy of the entire industry supply chain.